What is hot melt adhesive machine?

Generally speaking, hot melt adhesive machine is a kind of equipment that melt solid glue. Hot melt adhesive HMAS melt as temperature increase and solidify rapidly as cool down between two substrates.

Most heating machine has the ability to control the temperature, speed and the shapes of the melted glue. Through pressure device, the melted glue becomes liquid, and then goes to the coating machine.

Hot melt gluing machine is an electro-mechanical device.It has temperature heating control, pressure function, liquid conveying and extrusion coating functions.

Various Hot Melt Gluing Machine Types

There are many types, such as hot melt adhesive lamination machine, coating machine, tape coating machine, dispense machine, glass sealing machine.

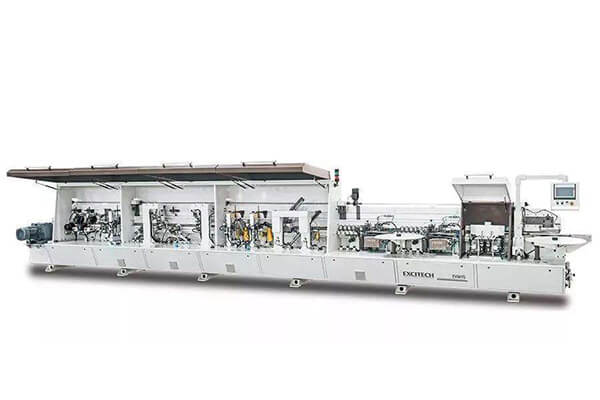

There are also hot melt glue box sealing machine, pur hot melt glue machine, case sealers, spraying machine, packaging machine, glue roller machine, edge banding machine.

Hot Melt Adhesive Machine Application Fields

Factory usually use hot melt adhesive machine for glue spraying, scraping, rolling, and injection. Below are some of the applications fields:

- Household products, like diapers, sanitary napkins, mouse traps, cockroach houses and other disposable products.

- Automotive industry, such as interior sealing, car lamp manufacturing, windshield assembly, air filter, non-woven composite lamination.

- Packaging industry, like carton packaging, cigarette case packaging, Tetra Pak packaging. Coating composite industry, like coating trademark paper, label double-sided tape, medical breathable tape.

- Others like shoe industry, printing, electronic product assembly, clothing, stickers, bookbinding.

Hot-melt glue machine entered Chinese market in the mid-1980s. Chinese machinery manufacturers made this kind of equipment in the 1990s. At first, only small industries use hot-melt glue machine in such as cosmetics, and then sanitary napkins. Later, the packaging industry slowly began to use hot melt adhesives. Therefore, in mainland China and Eastern European countries, the Middle East countries also began to use industrial hot melt adhesive machines and equipment.

Hot Melt Glue Machines Working Process

- Add hot melt adhesive to the melting tank;

- Heating melting tank; heating the hose and coating device;

- Start the pressurizing device to feed the glue;

- Start the coating device according to the process requirements.

Hot Melt Gluing Machines Daily Maintenance and Safety Precautions

- When installing, connect a grounding wire correctly and effectively. If not, any components will risk the danger of electric shock. Check the electric wire load capacity, and ensure enough insulation protection. Make sure correct voltage connection. Operate machine at specified voltage.

- Cut off power supply before carry out maintenance and repair. Do not wear earrings, watches, necklaces, bracelets, when disassemble or repair.

- Ask professionals to disassemble, inspect and adjust hot melt glue machine. Do not disassemble and repair the hot melt glue machine equipment alone.

- Do not touch the wire joints or other components that may be exposed to the outside.

- Stand on the plastic blanket for maintenance work. Never perform maintenance, on a flooded floor, or in a very humid environment.

- Wear safety gloves, goggles and long-sleeved work clothes when maintaining. Avoid burns by high temperature, liquid hot melt or machine surface.

- When loosening or installing the pressure joint, reduce the pressure to zero.

- When cleaning melting tank, avoid using fireworks or sharp hard tools. Avoid scratches on the Teflon non-stick inside coating.

- If there is air pressure or glue leakage from the hot melt adhesive machine, do not continue to operate. First, stop the machine, cut off power supply, and then reduce pressure to zero before overhauling.

GC Adhesives Team has great experience in provide suitable adhesive types to your gluing machinery. Whether for coating, or spraying, pellet, film, powder, we shall give effective solutions. Contact us for more advice.

Brilliant article! You rightly pointed out the various applications of hot melt adhesive machines like interior sealing, carton packaging, case packaging, and bookbinding. I would like to add two more applications of hot melt adhesives. These are bottle labeling and woodworking. Due to its multiple applications, hot melts prove to be versatile adhesives.